Trouw Nutrition shares 5 takeaways from FeedTechnoVision LATAM 2025

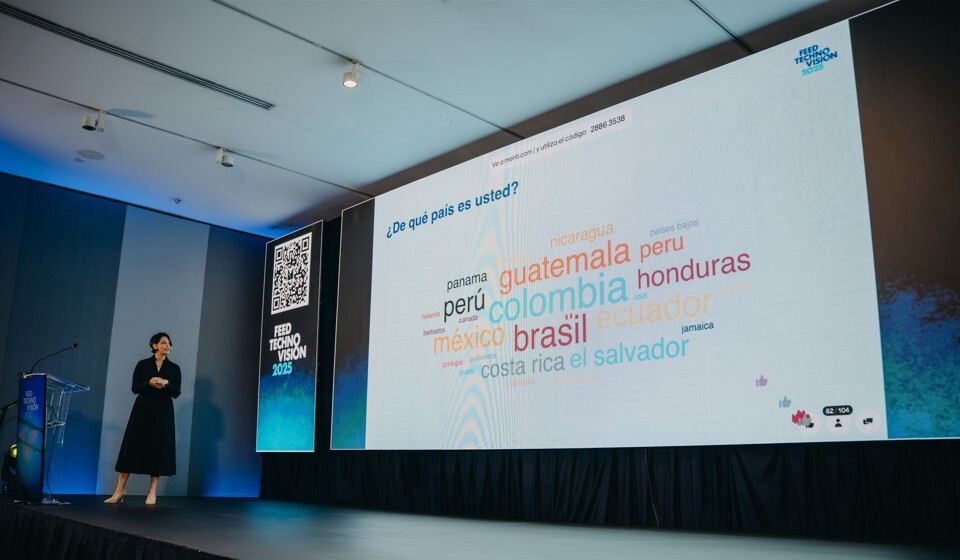

Building on previous FeedTechnoVision summits in Europe and Asia, the conference attracted more than 200 feed mill operators, quality control managers and nutritionists from the LATAM region

Trouw Nutrition, the livestock feed business line of Nutreco, organized FeedTechnoVision LATAM edition in Guatemala City, 2-3 October. Building on previous FeedTechnoVision summits in Europe and Asia, the conference attracted more than 200 feed mill operators, quality control managers, and nutritionists from the LATAM region to explore how collaboration, communication, and innovation can enhance the quality, consistency, and efficiency of feed production.

Why in LATAM. Why now:

LATAM’s animal protein markets continue to surge, growing over 4% per year — double the global growth in animal protein output. However, the adoption of feed technological innovations varies across the region, and raw material sourcing and sustainability issues present additional challenges. Throughout the conference, global feed thought leaders addressed these issues and explored approaches to accelerate innovation, enhance operations efficiency, and empower people across the feed production chain. Five takeaways from LATAM 2025 are shared below.

- Takeaway #1: Raw material and process optimization.

Feed industry consultant Gerardo Morantes noted that raw materials represent about 70% of feed production costs, making sure that reception, processing, and preservation of raw material integrity and waste reduction are priorities for efficient feed production. Technologies such as Near-Infrared Reflectance Spectroscopy (NIRS) and managerial approaches like Lean Six Sigma can help reduce variability and improve the consistency and quality of feed production. Empowering and educating operators is also essential to turning process control into feed mill success.

- Takeaway #2: Technology paired with people supports efficient, safe operations.

Integrated systems and technologies supporting processes such as weighing and flow control are vital for achieving consistent feed quality. José Gustavo Nuñez, Project Manager at Skretting, noted that integrating weighing systems into the programmable logic controller (PLC) architecture allows operators to visualize trends, detect deviations early, and make data-driven adjustments. Regular evaluation of raw material distribution helps minimise formulation errors, nutrient variation, and improve plant throughput.

Technology is also a cornerstone when it comes to feed safety. Antoniel Franco, Global Programme Manager Feed Processing and Quality at Trouw Nutrition, emphasized that continuous personnel training is essential to managing the risks posed by microbial and chemical contaminants. Systematic sampling, microbiological testing, temperature and moisture monitoring along with employee training must be an ongoing part of a feed safety programme.

- Takeaway #3: Prioritize pellet quality and microstructure.

Particle size can influence parameters that go beyond feed mill costs and productivity, affecting pellet durability and animal performance. Steam is an often underestimated but decisive factor in manufacturing durable, digestible, and hygienic feed. Water and steam quality contribute to energy efficiency and quality of the finished product. In remarks at FeedTechnoVision LATAM, Héctor Pacheco, Feed Mill Manager at Mountaire Farms, discussed how proper boiler maintenance, pressure regulation, and humidity control in the conditioner determine pellet consistency and affect pellet production.

Considering the economics of feed production, Wilmer Pacheco, Associate Professor at Auburn University, discussed how moisture loss and improper cooling processes contribute to shrinkage that reduces feed mill profitability. He noted that surfactants and organic acids can mitigate shrinkage loss while improving microbial safety. Pacheco advised feed mills not to sacrifice the pellet’s microstructure for hardness. Proper conditioning and cooling measures ensure that pellets produced are durable, consistent, and digestible with a low percentage of fines.

- Takeaway #4: People will make the difference.

Investing in training, communication, and cross-functional knowledge transfer are key to feed milling success. Operators’, maintenance managers’, nutritionists’, and quality managers’ responsibilities should be considered in context with how their work relates to all aspects of feed production. “When these roles have a more holistic understanding of the feed process, quality, and nutrition, efficiency can be enhanced throughout the production chain. Continuous capability development and cross-functional communication is key,” said Eng. Agustín Piedrahita, Key Account Service Manager at Trouw Nutrition.

- Takeaway #5: Create a culture of precision, control, and continuous improvement.

The efficiency and sustainability of feed production is not a destination but a continuous journey. Continuous monitoring and attention to precision controls and monitoring at every stage of production drives ongoing improvements. For José Maria Bello, Technical Manager, Nanta, feed manufacturing must bridge the gap between formulation requirements and processing reality. “To stay profitable, precision and effectiveness must go hand in hand ¬ and that means constantly evaluating and improving how we work," he stated. “Quality is a dynamic process, not a static goal.”

Beyond pelleting – Pet food and extrusion precision

A FeedTechnoVision LATAM session focused on extruded feeds examined the fast-growing pet food segment. María del Pilar Castiblanco, Key Account Manager at Trouw Nutrition, remarked on the fast-paced growth of the pet food market and the industry’s responsibility to deliver nutritious, sustainable, and palatable products. Michel Pereira, Technical Director at Famsun, reinforced the conference themes of key points on extrusion processing, with a strong focus on the requirements for precision and uniform drying.

Summarising the presentations, networking and insights shared at FeedTechnoVision LATAM, Pedro Caramona, Global Director Feed Safety & Quality at Trouw Nutrition, observed, “The path from process to performance depends on three aligned forces: technological and innovation adoption, operational discipline, and culture of knowledge sharing and collaboration. Together, they drive the region toward safer, smarter, and more resilient feed production.”