Pulsed Electric Fields in Food Production

Food quality and safety can be improved through pulsed electrical fields, according to Dr Ingrid Aguilo-Aguayo.Pulsed Electric Fields (PEF) involves the application of high-voltage energy (0.5-80kV/cm) in the form of short pulses (s to μs), leading to a minimum heating of the product. The principles of PEF processing on food work through electroporation.

This physical phenomenon is based in the response of the cell to PEF treatments, which could produce reversible or irreversible permeabilisation of the cell membrane, leading to a wide range of food applications.

The reversible permeabilisation induces an increase in the mass and heat transfer rates between cells and their surroundings, enhancing the efficiency of processes such as fermentation, expression, extraction and diffusion of plant metabolites.

On the other hand, the structural damages promoted by PEF have been demonstrated to be efficient for treating a large number of food products such as juices, milk, yogurts, soups, liquid eggs and even raw chicken.

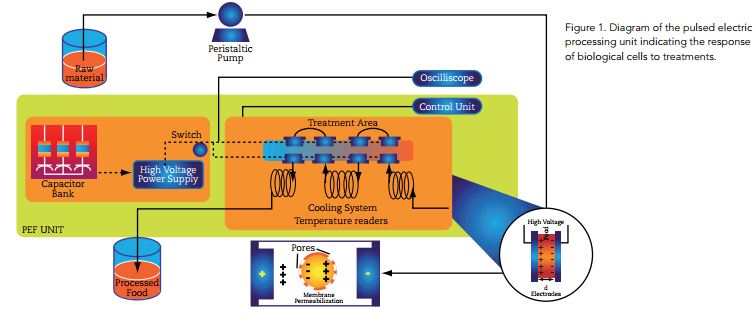

The PEF generation schematic consists of highvoltage power supply to charge the capacitors and a discharge switch that releases the stored electric energy in the form of an electric field through the product.

The PEF treatment chamber houses the electrodes delivering high voltage discharges to the food material placed between them. The product could flow through one or more treatment chambers configured for either static or continuous operations (Figure 1).

Moreover, the efficiency of the treatment will also depend on the PEF processing parameters such as electric field strength, total treatment time, pulse shape, pulse frequency, pulse width, polarity mode and temperature.

Potential applications of PEF for food

PEF can be used as a pretreatment of the drying process, in order to either enhance the drying rates, or to obtain a higher quality product in terms of structure or solid content – for example, PEF enhanced drying of red paprika in a fluidised bed dryer at 60ºC for 6h and air velocity of 1m/s.

The permeabilisation induced by PEF determined the enhancement of mass transport during drying. In fact, a reduction of approximately 25 per cent of drying time was observed in PEF pre-treated samples in comparison to those control samples.

The permeabilisation induced by PEF on food membranes could also positively affect mass transfer in juice extraction. The use of PEF in combination with pressing steps at three-bar pressure was a suitable method of increasing apple juice yield, affecting the quality of extracted juice positively (Donsí et al., 2010).

PEF could also enhance the extraction of metabolites of commercial interest, as well as enhance the recovery of soluble substances from different fruit and vegetable tissues. Some reports also indicate that PEF processing could represent a viable option for enhancing the extraction of phenolic compounds from skin cells of grapes during the maceration steps in winemaking process, without altering the quality and with moderate energy consumption.

Since Ireland has an important brewing and cider production, the great potential of PEF for food recovery and waste reduction could offer Irish food industries important economical savings and high value products.

Preservation of food products by PEF

PEF has been suggested as an alternative technology to obtain safe, high quality, nutritious foods with a shelf-life similar to that attained with conventional thermal pasteurisation. The optimisation of PEF treatment conditions, contributing to the standardisation of PEF processing for the destruction of both pathogenic and spoilage microorganisms in milk and several fruit juices has been developed.

For instance, populations of Salmonella enteritidis, Escherichia coli and Listeria monocytogenes in melon juice were reduced by up to 3.7 log cycles when applying 35 kV/cm for 1,709s (Aguiló-Aguayo et al., 2011).

Although the processing conditions have a strong influence on the inactivation of microorganisms by PEF, the fluid medium, the target microorganism and the microbial characteristics also can exert an important influence on the effectiveness of the treatment.

Among bioactive compounds, vitamin C has been one of the most studied due to its heat-liability. In general, reports indicate that vitamin C is less affected by PEF treatments than by conventional treatments in very different products such as orange juice, apple juice, strawberry juice, tomato juice and fruit juice-soy milk blend.

Recent studies have also suggested that the antioxidant potential of various fruit juices increased after PEF processing compared to the untreated juice because of the increment in their carotenoid content.

An increase in the lycopene content and a significant enhancement in the total content of carotenoids in orange juice and in an orange juice-milk beverage have been reported after PEF processing.

Although the reason for these results is not known, it could be speculated that carotenoid conversions could be triggered by the PEF treatments (Odriozola-Serrano et al., 2011). Different susceptibilities to PEF processing have been observed for enzymes affecting the stability of health-related compounds, as well as important flavour compounds of juices such as lipoxygenase (LOX) and β-glucosidase (β-GLUC).

An 80 per cent reduction of LOX activity was observed when tomato juice was exposed to PEF, whereas only 33 per cent and 20 per cent inactivation was obtained when processing strawberry and watermelon juices, respectively.

Nevertheless, similar LOX inactivation values were observed after processing by conventional heat treatments. On the other hand, β-GLUC was activated up to 115 per cent after treating strawberry juice. The increment in the β-GLUC activity of PEF-treated juices was related with a high 2,5-dimethyl-4-hydroxy-3(2h)-furanone (DMHF) release, one of the major volatile compounds determining strawberry-like aroma, provided that this enzyme catalyses the hydrolysis of DMHF from its glucosidic precursor (OdriozolaSerrano et al., 2011; Aguiló-Aguayo et al., 2008). On the other hand, correlations between colour and inactivation of oxidative enzymes such as peroxidase or polyphenoloxidase have been also established for PEF-treated strawberry, watermelon, carrot and orange juices.

PEF treatment led to an almost complete reduction in their initial enzyme activity, as well as a great preservation of their colour. PEF has been shown to be an interesting technology for food processing since high-quality, safe and shelf-stable products can be obtained without significant depletion of their nutritional and sensory properties.

Dr Aguiló-Aguayo has begun a project in Teagasc Food Research Centre, Ashtown, together with Dr Juan Valverde with the objective of determining the effects of PEF in carrot and broccoli food products and their associated bioactive content, related specifically to glucosinolates and polyacetylenes.

The Institute of Food and Health, University College Dublin, will be also integrated in the project.