Beef Grades and Carcass Information

The U.S. Department of Agriculture (USDA) uses a dual grading system for beef carcasses: a Yield Grade for estimating cutability and a Quality Grade as a comprehensive evaluation of factors that affect beef palatability, says the this Mississippi State University Extension Service, report.

The USDA grades segregate carcasses into similar categories based upon cutability and estimated palatability. Yield Grade identifies differences in cutability or yield of boneless, closely trimmed retail cuts from the round, loin, rib, and chuck. Quality Grade indicates the relative desirability or expected palatability of the meat in a carcass or cut.

A highly-trained USDA employee known as a USDA grader or approved electronic instrumentation assign beef Yield Grades and Quality Grades to beef carcasses postharvest following a period of chilling typically ranging from 18 to 48 hours. Grading beef carcasses is optional.

Carcasses can receive both the Yield Grade and Quality Grade or only one of these grades. To have beef carcasses graded, a packing plant must request that carcasses be graded and must also pay for this service.

While not all beef carcasses from U.S. fed cattle are designated for grading, most are now officially graded. More than 95 per cent of beef cattle harvested receive USDA grades.

More and more fed cattle are now sold by cattle feeders, to packers, in transactions such as “grade-and-yield” or “on-agrid” that require that all carcasses in such groups be officially Yield Graded and Quality Graded. Some packers may also have their own in-house grades and premium/ discount programs independent of USDA grades. Questionnaires from the 2005 National Beef Quality Audit suggested that more than half of the fed cattle marketed in the U.S. are now sold “on the grid” or “in the beef.” In addition, the per centages of source and age verified cattle are small but increasing.

Carcass Traits

Yield Grades and Quality Grades are determined from observing and measuring specific carcass traits. Additional carcass traits not used in the official USDA grading system, such as tenderness, also affect beef end product. Individual traits impact carcass grades and product value in different ways. The following section lists and discusses individual carcass traits. Data from the Mississippi Farm to Feedlot program from 1993 through 2007 are included where appropriate. The Farm to Feedlot program facilitates retained ownership of Mississippi feeder cattle through the feeding phase. The program provides feedlot performance and carcass data, which can be linked to individual sires and/or cows, to aid in genetic selection for improved performance.

Hot Carcass Weight

Hot carcass weight (HCW) is the hot or unchilled weight of a beef carcass after harvest and removal of the hide, head, gastrointestinal tract, and internal organs. It is sometimes reported as carcass weight. Carcass weight is the most important factor in determining carcass value when cattle are sold. Regardless of how cattle are marketed, whether on a dressed-weight basis or on a value-based grid, carcass value is always tied to the weight of the carcass.

Therefore, in many cases, a heavier-weight carcass may have a greater total value than a lighter weight carcass because of the difference in total pounds, even if the lighter carcass is more valuable on a per-pound basis. Hot carcass weight is also used in Yield Grade calculations. Generally, the per centage of retail product decreases as cattle increase in weight because of increased fat deposition, but this depends on the growth stage of the animal.

Packers monetarily discount heavyweight and lightweight carcasses that do not fit their specifications. Generally, as carcass weights move further away from baseline specifications, discount levels increase.

Large fluctuations in carcass weights create challenges during harvesting and processing. Heavy carcasses can break or damage overhead rail systems in packing plants, and light carcasses may be too short for stationary equipment used in carcass fabrication.

Additionally, wholesale beef cuts that are outside desired size ranges are difficult to manage and market in a boxed-beef system.

The National Beef Quality Audit outlined a range of 650 to 850 pounds as an industry target for carcass weight. Carcass size is genetically influenced and can be changed with an emphasis on frame size and growth rate in breeding decisions. Management of days on feed, implant regimes, and feeding programs can also be changed to affect carcass weights. Mississippi Farm to Feedlot program data show that the 15-year average for hot-carcass weight was 750 pounds.

Dressing per centage

Dressing per centage is hot carcass weight as a per centage of the live weight of the animal at harvest. It typically ranges from 60 to 64 per cent for the majority of fed cattle and averaged 64 per cent for the Mississippi Farm to Feedlot program cattle from 1993 through 2007. To calculate dressing per centage, divide hot carcass weight by animal live weight. The result is a per centage. For example, if a 1200-pound steer produces a 768-pound carcass, the dressing per centage is 64 per cent (768 ÷ 1200 x 100 per cent = 64 per cent). Similarly, animal live weight times the dressing per centage yields the carcass weight.

Ribeye area (REA) is an indicator of the amount of lean muscle associated with a carcass. As the REA increases, the amount of muscle in a carcass increases. It is an important factor in determination of Yield Grade. As ribeye area increases, Yield Grade tends to improve.

Ribeye Area

Ribeye area is determined by measuring the area of the longissimus dorsi (ribeye) muscle exposed by cutting or “ribbing” the carcass between the 12th and 13th ribs. Ribeye area is expressed in square inches and is often determined using a grid device, analysis of ribeye tracings, or most recently, electronic vision instruments that are basically computerized cameras.

Within the beef industry, ribeye size varies greatly. Both excessively small and excessively large ribeyes are quality challenges for the beef industry. An optimum range for ribeye area is 11 to 15 sq. in. Ribeye area targets should be approximately 1.6 to 1.8 sq. in. per 100 pounds of carcass weight. Results from the Mississippi Farm to Feedlot program show that ribeye area averaged 12.95 sq. in., and ribeye area per 100 pounds of carcass weight (cwt) averaged 1.74 sq. in.

Fat Thickness

Fat thickness (rib fat or back fat) is a measure of external fat thickness on a carcass. External fat is the most important determinant of retail yield. Fat thickness is measured at a point ¾ of the length of the longissimus dorsi muscle from the split chine bone.

As fat thickness increases, cutability and per centage of retail product decrease, resulting in less desirable Yield Grades. Cutability is the per centage yield of closely trimmed, boneless retail cuts. Excessively low amounts of external fat on a beef carcass are undesirable, as well. This can increase the risk of cold shortening (chilling of the carcass too rapidly, leading to increased toughness). An optimum range for fat thickness is 0.2 to 0.5 inches. Mississippi Farm to Feedlot program carcass back fat thickness averaged 0.48 inches over 15 years of the program.

Internal Fat

Kidney, pelvic, and heart (KPH) fat is also called internal fat. Internal or KPH fat is expressed as a per centage of hot carcass weight and is used in Yield Grade determination. The per centage of retail product yield decreases as KPH fat increases.

Intramuscular Fat

Intramuscular fat (IMF) is often called marbling. Marbling refers to the flecks of fat within the muscle tissue. Sufficient marbling is important for beef tenderness, juiciness, and flavor. Degree of marbling is the primary factor determining Quality Grade. For official grading purposes, marbling is assessed in the longissimus dorsi muscle exposed between the 12th and 13th ribs. Nine degrees of marbling are recognized by the USDA Grade Standards. These nine marbling scores and their common abbreviations are listed below.

- Abundant 00-99 (AB)

- Moderately abundant 00-99 (MAB)

- Slightly abundant 00-99 (SLAB)

- Moderate 00-99 (MD)

- Modest 00-99 (MT)

- Small 00-99 (SM)

- Slight 00-99 (SL)

- Traces 00-99 (TR)

- Practically devoid 00-99 (PD)

Each marbling score is divided into 100 subunits. Superscripts ranging from 00 (least amount of marbling) to 99 (greatest amount of marbling) are assigned within each marbling score. Average marbling score over 15 years of the Mississippi Farm to Feedlot program was Small, with the trend being toward increasing marbling score.

Maturity

Maturity is another factor affecting carcass Quality Grade. It is subjectively evaluated because chronological age (age in months) of a beef animal is not always known at harvest. Therefore, physiological estimators of age are used to evaluate carcass maturity.

Physiological age may not be the same as the actual animal age. The physiological maturity of a carcass is determined by evaluating the size, shape, and ossification of bone and cartilage (especially the split chine bone) and the color, texture, and firmness of the lean tissue exposed at cut between the 12th and 13th rib. Lean color becomes darker and texture becomes coarser with age. Factors other than age can alter lean color and texture, so most of the emphasis on maturity evaluation is placed on observation of bone characteristics and cartilage ossification.

To estimate maturity, a USDA grader evaluates the cartilage associated with the backbone (spinal column) and the color and shape of the ribs. When a beef animal is harvested, the carcass is split down the spinal column. When the carcass is split in half, the grader can evaluate cartilage associated with the spinal column and the shape and color of the ribs. At the dorsal (backside) end of each vertebra is a section of cartilage, which is referred to as the cartilaginous tips or buttons. As cattle age, these tips ossify or change from soft, pearly-white cartilage to hard, porous bone.

Maturity is then estimated based on the status of these buttons and the degree to which they are ossified. The rib bones are quasi round with a red, youthful appearance in young cattle. As cattle age, the ribs flatten out and develop a white appearance.

Carcass maturity is scored using letters A through E, with A’s being the least mature and E’s being the most mature. Carcasses displaying advanced skeletal maturity are referred to as “hard bones,” and associated price discounts normally apply.

|

USDA Maturity Scores and Associated Cattle Ages

|

|

|---|---|

| A |

9 to 30 months (2 and a half years)

|

| B |

30 to 42 months (2 and a half to 3 and a half years)

|

| C |

43 to 72 months (3 and a half to 6 years)

|

| D |

73 to 96 months (6 to 8 years)

|

| E |

97 months or more (greater than 8 years)

|

Tenderness

Inadequate tenderness of beef was cited in the 2005 National Beef Quality Audit as one of the top quality challenges facing the beef industry.

Although tenderness is not used in Quality Grade or Yield Grade calculations, it plays an essential role in consumer satisfaction. Tenderness is objectively measured with a Warner-Bratzler shear force device. A good industry target for tenderness is a Warner- Bratzler shear force value below 8 pounds.

Acceptable tenderness levels depend in part on where and how the product will be marketed. Currently there is no easy way to assess tenderness in making beef purchasing decisions, so restaurants often base their purchasing decisions on Quality Grade instead. Many food service establishments, particularly fine-dining establishments, seeking a good eating experience for their customers recognize that tenderness is an important component of the experience.

Tenderness is impacted by cattle genetics, preharvest cattle management, and postharvest factors. There is likely to be increased emphasis on selection of cattle for beef tenderness as selection tools become available and as tenderness level reporting develops. Beef cattle breed associations are beginning to address tenderness as a trait of interest in national cattle evaluations.

Research efforts are under way to identify genetic markers for tenderness and develop selection tools based on this information. Many preharvest management factors impact tenderness as well include animal nutrition, stress, and health. Postharvest factors impacting tenderness include carcass aging time, carcass electrical stimulation use, postmortem pH, cooking temperature, cooking method, and degree of doneness.

USDA Beef Carcass Grades

USDA Yield Grade

The USDA Yield Grades classify carcasses for differences in cutability or yield of boneless, closely trimmed retail cuts from the round, loin, rib and chuck. The five Yield Grades are numbered 1 through 5. Carcasses in Yield Grade 1 have the highest cutability or per centage of retail product, while carcasses in Yield Grade 5 have the lowest cutability or per centage of retail product. Mississippi Farm to Feedlot program cattle averaged Yield Grade 3 over a 15-year period.

The Yield Grade of a beef carcass is determined by considering four characteristics: (1) the amount of external fat (back fat), (2) the amount of KPH fat, (3) the area of the ribeye muscle, and (4) the hot carcass weight.

Yield Grades are based on the following equation: Yield Grade = 2.50 + (2.5 x adjusted fat thickness, inches) + (0.2 x per centage kidney, pelvic and heart fat) + (0.0038 x hot carcass weight, pounds) – (0.32 x area of ribeye, square inches)

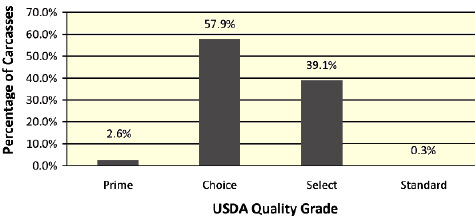

Comparison by Yield Grade of federally inspected beef carcasses in 2007

Numerical Yield Grades calculated using this equation are rounded down to the nearest whole number for assignment of a distinct Yield Grade from 1 to 5. For example, a beef carcass with a calculated Yield Grade of 2.98 would be classified as Yield Grade 2, not Yield Grade 3. Therefore, it is possible for a change in a characteristic influencing Yield Grade to change the calculated Yield Grade in terms of decimals as indicated in the following table while not changing the actual assigned Yield Grade of 1, 2, 3, 4, or 5.

| Effects of various factors on beef carcass Yield Grade | ||

| Chracteristic affecting Yield Grade | Change in characteristic | Resulting change in numerical Yield Grade |

|---|---|---|

| Fat thickness | Increase | Increase |

| per cent of kidney, pelvic, and heart fat | Increase | Increase |

| Carcass weight | Increase | Increase |

| Ribeye area | Increase | Decrease |

Because of the scale and speed of modern packing plants (many plants grade 300 to 400 beef carcasses per hour), instead of measuring these factors and using the equation to determine Yield Grade, a USDA grader will read the carcass weight noted on a tag applied to the carcass by the packing plant; estimate ribeye area, external fat, and KPH fat; and then assign a Yield Grade based on these values.

USDA Quality Grade

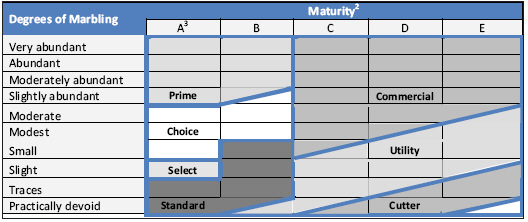

Quality Grades evaluate factors that affect beef palatability (eating quality and desirability). Marbling and carcass maturity (including bone characteristics and the color, firmness, and texture of the exposed lean on the cut surface between the 12th and 13th rib) determine Quality Grade. A better Quality Grade is achieved with more marbling and lower carcass maturity. Note the differences in marbling at the same level of maturity between the different Quality Grades in the above table and within a Quality Grade in the following table:

2 Maturity increases from left to right (A through E).

3 The A maturity portion is the only portion applicable to bullock carcasses.

Beef Quality Grades are typically divided into thirds or halves for improved segregation of beef carcasses. Meat judging, carcass evaluation, and value-based marketing programs use these subdivisions. The Prime Grade is divided into thirds (High, Average, and Low), and the Choice Grade is also divided into thirds (High, Average, and Low). The Select Grade is divided into halves (High and Low), and the Standard Grade is also separated into halves (High and Low).

Symbols used to designate these Quality Grade divisions are: + (high), o (average) and – (low). For example, Choice– indicates the lower one-third of the Choice Grade. A “No Roll” category refers to all carcasses that do not meet the requirements for the USDA Select Grade and would likely grade USDA Standard if graded. A grade stamp is not rolled on these carcasses. Bull beef is not Quality Graded, and cow beef is not eligible for the Prime Grade. In addition, Commercial, Cutter and Canner grades are not applicable to bullock beef.

Mississippi Farm to Feedlot program cattle averaged Select + over 15 years, with a trend toward increasing Quality Grade. The per centage of these cattle grading Choice – or better was 43 per cent and also displayed an increasing trend.

Carcass Defects

Dark Cutters

Dark-cutting meat is characterized by a color range from dark red to nearly black and has both a sticky texture and a high water-holding capacity. Dark-cutting beef results from low muscle glycogen at the time cattle are slaughtered. Glycogen depletion in muscles of cattle can be caused by strenuous muscular activity, stress-induced adrenalin secretion, and severe energy restriction for several days before slaughter. Highly excitable cattle are more likely to produce dark cutter carcasses than calmer cattle.

The greatest problem with dark-cutting beef is consumer rejection because of its color. The quality of dark-cutting beef is lower than normal. It has significantly shorter shelf-life than normal beef and greater water-holding capacity, which are more conducive to bacterial growth. For these reasons, dark-cutting beef is severely discounted. The 2005 National Beef Quality Audit reported that 1.5 per cent of beef carcasses were dark cutters.

Blood Splash

“Blood splash” describes localized hemorrhaging (bleeding) within the muscles of a beef carcass. This condition results when the capillaries in the muscles rupture because of abnormally high blood pressure before exsanguination (blood draining). Lengthy delays between stunning and sticking during harvest may cause this. The incidence of blood splash reported in the 2005 National Beef Quality Audit was1.7 per cent.

Calloused Ribeyes

“Calloused” ribeyes are the result of steatosis of longissimus muscle. Connective and fatty tissues can spread into areas of muscle, creating a callus or section of fatty tissue within the muscle. The causes of muscular steatosis are unknown, but strenuous muscle exertion may be involved. The 2005 National Beef Quality Audit reported a calloused ribeye incidence of 0.3 per cent.

Bruises

Trim loss is most often from fecal contamination but can occur from deep tissue bruising or severe abscesses. Trim loss from bruising can impact carcass value, particularly when high-value sections of the carcass are involved. Trimming that damages the major muscle groups of the wholesale round, loin, rib, or chuck is a “major” defect.

The 2005 National Beef Quality Audit revealed that 35.2 per cent of beef carcasses were bruised. This was down from 46.7 and 48.4 per cent in the 1995 and 2000 audits. Nearly one-third of bruises in 2005 appeared on the loin. Following Beef Quality Assurance guidelines, such as adhering to recommended injection site locations, dehorning, and handling animals properly, can help minimize bruising and resulting trim loss.

Organ Condemnations

In addition to being paid for the value of a beef carcass, producers are paid a drop credit that includes the value of hide, head, organs, and blood. Variety meats are produced from carcass offal such as livers, hearts, and tongues. Condemnations of these products reduce the value of harvested beef animals.

The 2005 National Beef Quality Audit showed that 24.7 per cent of livers were condemned, an improvement from the 30.3 per cent of livers condemned according to the 2000 Audit. Liver condemnations were primarily from abscesses and liver flukes. Lung condemnation incidence was 11.5 per cent. Pneumonia was the leading cause of lung condemnations. Tripe condemnation occurred at a rate of 11.6 per cent. The main cause of tripe condemnation was contamination with metallic objects such as nails, cotter pins, and wire. In addition, 9.7 per cent of tongues were condemned. Whole carcass condemnations were not found.

Conclusions

Carcass uniformity and consistency vary greatly among beef cattle. Gender differences also exist in carcass grades.

The 2005 National Beef Quality Audit identified the top ten greatest quality challenges facing the beef industry. Many of these quality challenges can be addressed by using beef carcass information for improved genetic selection practices. They can also be affected by making cattle management decisions with the quality and value of the beef end product in mind.

Using this information, beef cattle producers can take the following actions to improve carcass value:

- Improve cattle genetics

- Increase record keeping

- Increase individual animal identification

- Improve animal handling and transportation practices

- Collect and utilize carcass data

- Follow Beef Quality Assurance guidelines

Carcass traits are important in determining Beef Yield Grades and Quality Grades. They are an important consideration for beef cattle producers in cattle selection and management, especially when cattle ownership is retained through harvest and cattle are marketed on value-based carcass grids. The 2005 National Beef Quality Audit indicated that 62 and 42 per cent of branded beef programs had specifications for marbling and Yield Grade, respectively. Producers who provide carcass information to potential buyers position themselves to be rewarded for producing a quality product. For more information on beef grading, carcass information, or related topics, contact an office of the Mississippi State University Extension Service.

Apirl 2009