Ultrasound Scanning Beef Cattle for Body Composition

Ultrasound scanning for carcass traits is a useful tool for obtaining valuable carcass information from a live animal, says a Mississippi State University Cares report, prepared by By Jane A. Parish, Justin D. Rhinehart and Rhonda C. Vann.Ultrasound technology uses sound waves to develop images of body composition. Body composition traits that can be measured include 12th to 13th rib fat thickness, rump fat thickness, ribeye area, and intramuscular fat percentage (marbling). Each of these traits is at least moderately heritable and is significant in the determination of red meat quality and yield for individual animals.

Body Composition Traits

Rib Fat

Rib fat (also called fat thickness or backfat) is an external fat measurement taken between the 12th and 13th ribs. It is measured in inches. Rib fat is used in USDA yield grade calculation and is the most important determinant of retail yield. Higher amounts of rib fat decrease cutability and produce less desirable yield grades.

Ribeye Area

Ribeye area is the surface area of the longissimus dorsi (ribeye) muscle at the 12th rib interface on the beef forequarter. Ribeye area is expressed in square inches. Retail product yield increases and numerical yield grade decreases as ribeye area increases. This image is often the most difficult to collect and requires a highly skilled interpreting technician. Both rib fat and ribeye area are taken from the same image (Figure 1).

Rump Fat

Rump fat refers to the depth of fat at the juncture of the gluteus medius and superficial gluteus medius muscles. This measurement is expressed in inches. It is taken from an image collected between the hooks (hips) and pins of the animal. The rump fat measurement, together with the rib fat measurement, is used to determine more accurately the overall external body fat. This improves the accuracy of predicting percent retail product. In most cases, an animal will exhibit more fat over the rump than the rib, so often more variation is displayed in rump fat measurements than rib fat measurements. This image is highly repeatable and is the least difficult to collect or interpret.

Scanning locations on the live animal are illustrated in Figure 3. Intramuscular fat percentage is measured at position 1, ribeye area and rib fat thickness are measured at position 2, and rump fat thickness is measured at position 3.

Intramuscular Fat

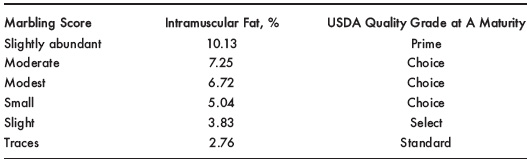

Intramuscular fat percentage (%IMF) is the percentage of fat in the ribeye muscle. It is often called marbling and is observed as flecks of fat in lean tissue. Degree of marbling is related to intramuscular fat percentage and is the primary factor determining quality grade (Table 1). Higher levels of intramuscular fat improve quality grade. This measurement should be collected when cattle are maintaining a high level of nutrition. The field technician collects four images (Figure 2), and the values generated by the interpreting software are averaged for an overall intramuscular fat percentage.

Table 1. Relationship between marbling score and intramuscular fat percentage.

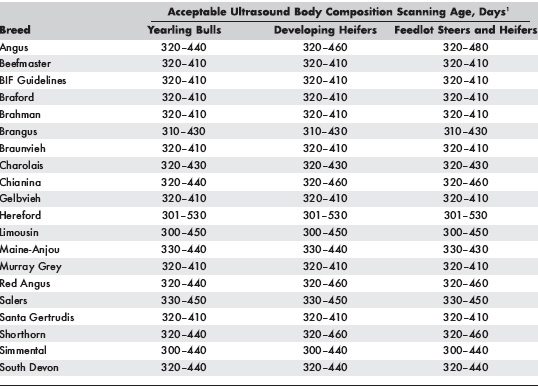

Acceptable Scanning Ages

Yearling bulls and heifers can be scanned at approximately 365 days of age to provide a good indication of how sibling steer and heifer mates will perform on the rail. Each breed association has established a window for age at scanning that must be complied with in order for the data to be used in the national cattle evaluation (Table 2). Consult with the respective breed association for current scanning age guidelines.

Barnsheets

Abarnsheet is a form that includes information such as herd ID, tattoo, sex, birth date, and registration number of each calf to be ultrasound scanned. Breed associations require that barnsheets be submitted with ultrasound scan images, so every animal scanned for breed association data submission must be on a barnsheet. For breeds that use ultrasound body composition data in expected progeny difference (EPD) calculations, barnsheet reporting is critical to ensure that scan results are properly reported to breed associations for EPD updates. For cattle not listed on preprinted barnsheets, the breeder must provide the necessary animal information to the ultrasound field technician for inclusion on the barnsheet at the time of scanning. This may be necessary if there are delays in data submission or registration and weaning performance paperwork processing.

Obtaining barnsheets before scanning is the responsibility of the cattle breeder, not the ultrasound field technician. To obtain a barnsheet from a breed association, a minimum amount of data must be on file with the association for the cattle to be scanned. Cattle must be registered with the association, and some breed associations require weaning weights before barnsheets will be created. Preprinted barnsheets often are distributed to breeders along with weaning performance reports. Barnsheets also may be accessed and printed by breed association members through breed associationWeb sites as part of their online accounts.

Review barnsheets before scanning to make sure all data needed to complete the sheets can be readily supplied at scanning. Barnsheets require the breeder to specify the contemporary grouping, management, and diet of the animals. Acontemporary group describes cattle of similar age and sex that were managed the same and had performance data collected as a group.

Improper contemporary group reporting will cause performance results to be incorrect. Note that breed associations often require a minimum contemporary group size for ultrasound body composition scan data to be used in EPD calculations, for yearling adjustments, or for performance ratios to be computed.

Each breed association provides specific management or test type codes (abbreviations or numbers designating animal management, such as ranch test, central test, developing heifers, and feedlot) and diet codes (abbreviations or numbers describing how the animals were fed, such as specific thresholds for concentrate feed levels). Look on the barnsheets or breed association Web sites for keys to these codes and code descriptions, or contact the breed association directly for this information.

Table 2. Acceptable age windows for ultrasound body composition scanning by beef cattle breed.

1Current as of June 2008. Refer to the specific breed association for updates.

Arranging Ultrasound Scanning Services

An Ultrasound Guidelines Council-certified technician can perform ultrasound body composition scanning services for a fee (Figure 3). The U.S. Beef Breeds Council charged the UGC with responsibility for developing, maintaining, and governing the proficiency-testing protocol and standards for beef cattle ultrasound technician certification. The UGC coordinates proficiency testing and certification for image collection (field certification) and laboratory interpretation (lab certification). Scheduling for a UGC-certified technician to scan cattle often needs to be done well in advance of the desired scanning date. Breed associations may have additional breed-specific ultrasound guidelines and publish a list of technicians that are certified for the particular breed.

It may be advantageous for several producers in an area interested in having their bulls scanned to arrange for a technician to service multiple farms in one area in one trip. The Mississippi Beef Cattle Improvement Association facilitates ultrasound body composition scanning of registered Mississippi cattle by accommodating ultrasound scanning sessions at centralized locations for multiple breeders at one time. This may help lower the cost of scanning for an individual farm by spreading the travel costs of the technician across several farms.

Preparing for Scanning

A grounded 110-volt electrical outlet must be provided for the field technician to use with the scanning equipment. Generators are not a desirable power source. Because cattle must be dry in the scanning regions, covered cattle holding and handling facilities may be needed in the event of precipitation. Severe weather may dictate that the scanning session be postponed until conditions become acceptable for scanning. Be prepared to provide supplemental heat for scanning equipment and oil if the outside temperature is too cold. Covered or shaded cattle handling facilities are needed to keep animals out of direct or bright sunlight during scanning. This allows the field technician to view the images on the monitor.

Cattle should be restrained in a squeeze chute with side panel doors during scanning to ensure image quality and ease of scanning. Cattle must be adequately clipped (within one-half of an inch; many technicians clip shorter than this) and cleaned in the region of scanning. Check with the field technician in advance to decide if the breeder needs to provide clippers, electrical extension cords, vegetable oil, paper towels, or other supplies at scanning. It may be useful to keep an extra set of clippers and clipper blades on hand in the event that there is a problem with the original clippers used.

Scanning and Image Processing

Individual animal weights must be recorded within 7 days of when the cattle are scanned. Record these weights on the barnsheets for the technician to submit to the authorized image interpretation lab along with the ultrasound images. Ideally, weights are collected at the time of scanning to reduce the number of times cattle must be handled. Some breeders choose to collect all yearling performance data (weights, scrotal circumference measurements, hip heights, temperament scores) at the same time cattle are ultrasound scanned for body composition. If the scan weight is to be used as a yearling weight, the breeder must submit the weight as a yearling weight to the breed association. This weight will not automatically be used as a yearling weight.

The ultrasound field technician should submit collected images and associated completed barnsheets to an authorized lab for interpretation. Breeders must be sure to leave barnsheets with scanning technicians instead of submitting them to the breed association. The field technician should be familiar with breed association requirements regarding acceptable image interpretation labs.

Image processing fees typically are charged for image interpretation services. The ultrasound field technician may pay these fees directly and then include the charge in an invoice to the breeder or may request that the breeder send payment directly to the authorized lab. After scan data interpretation is completed, scan results are then sent to the respective breed association(s) for adjustments and EPD calculations. Breed associations then provide summaries of scanning results and related performance information to breeders.

Ask the field technician how long it generally takes for image processing to be completed and results reported to the breed association and/or breeder. Breeders will typically be notified by scanning technicians if errors are found during image processing or by breed associations during report processing. Potential errors can include bad or missing images, incomplete barnsheets, unpaid scanning or image processing fees, missing weaning weights, or animals not found in breed association databases. If an unreasonable amount of time passes after scanning with no feedback on results, contact the scanning technician and/or breed association to track down and help resolve any potential problems. Results may be reported by e-mail, mail, or member-specific screens on breed association Web sites.

Conclusions

Ultrasound scanning technology is a useful tool for collecting body composition data on live animals. The resulting data are less expensive and time consuming to collect compared with actual harvest data from beef carcasses. This technology allows seedstock producers to collect body composition data on prospective breeding animals for use in genetic improvement efforts. Ultrasound scanning results help breeders select cattle that best fit market specifications. This information provides breeders with powerful information for seedstock marketing as well. For more information on ultrasound scanning for body composition traits, contact an office of the Mississippi State University Extension Service.

December 2008